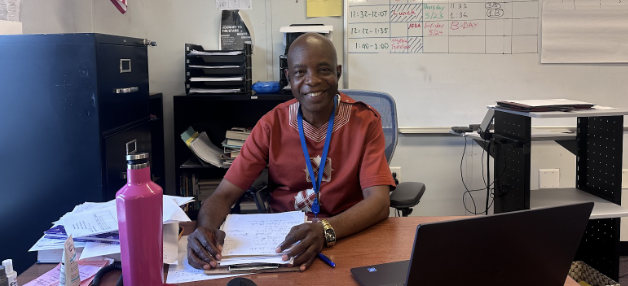

In a groundbreaking endeavor to build a vehicle from the ground up, Mr. Castro’s classes are trying to create excitement for Arlington Tech’s distinctive educational opportunities. Mr. Castro is the instructor of the Auto Collision class at ACC. This year, his classes are starting a new project to build an electric vehicle from scratch. All of the parts were delivered to them from the company that supplies schools with this project. Mr. Castro has been trying to do this project for years, having applied to the program multiple times before. There have only been 289 other models built, with the program running for 11 years. It will be a completely electric vehicle with a traction battery and an electric motor. The students will be doing all of the wiring and tasks similar to building a vehicle in a factory. The vehicle, despite common belief, is not actually a car. If they were to register it, it would be a motorcycle because it only has three wheels.

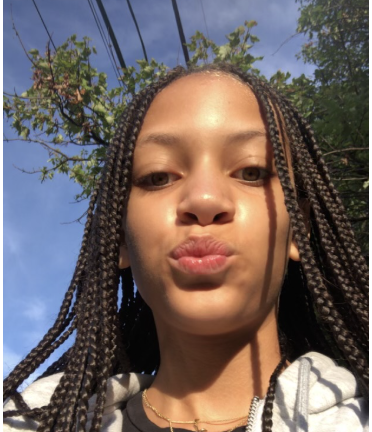

All five of Mr. Castro’s classes – 2 Maintenance & Light Repair classes, 2 Collision Repair I classes, and the advanced class – are working on the project. The advanced class is the head of the project, with Charlie Kubana, a senior, being the general manager. The creation of the electric vehicle is Charlie’s Capstone project. It is a great opportunity to show the community how valuable the experiences you can get at ACC are. It could inspire younger students to want to come here and do something impactful like this their senior year. His project represents everything that he has learned at this school, which is exactly what a capstone project is supposed to show. Charlie has been building stuff for years, so he was a great choice to lead the project.

Everyone in Mr. Castro’s classes will be given a role in the project, with Charlie delegating the work between the levels of the classes. So far, the MLR class has taken the car apart, and the Collision Repair I students are sanding and preparing the car for paint. After they are done, the advanced class will paint the car. Every time a class gets the car, they will be doing a completely new task. This allows everyone to contribute, despite their skill level or knowledge. Mr. Castro is working with Mr. Kivitz to involve his engineering classes to work on upgrading the car in future years. They hope to extend the upgrades for 3 years to allow many people to have a part in such a valuable experience.

The parts arrived around 4 weeks ago, and they are about 3 weeks into the project. There was a slight delay when Mr. Castro was out for a week, but everything remains on track. All of the parts have arrived, and they are focusing on safety for their first unit. The advanced class students are creating posters and signs to promote safety, as well as creating an overall safe environment to work on the car. They have estimated that it will take around 17 weeks to completely finish the project. The goal is to complete the car before June, before school lets out, so they can attend some car shows and the Arlington Country Fair with the vehicle. In other schools, the vehicle has taken longer than this, with one case lasting for over 7 years. It is a challenge to get it done this quickly, but the group of students working on the car at ACC have proven more than capable. They plan to modify the car in later years, doing things such as adding carbon fiber parts and upgrading the hardware to make it more powerful. This project is a perfect example of the distinctive experiences that are offered at Arlington Tech, and a great way to show that off to future students.